Innovation and Production

The production of Pico lace follows a traditional process passed down through generations. Over time, the techniques have evolved, adapting to market demands and new generations of lace makers while preserving the care and precision that characterize this tradition. Moreover, the lace makers of Pico have been recognized at exhibitions and events, introducing innovations to their craft and keeping a centuries-old practice alive.

MANUFACTURING PROCESS

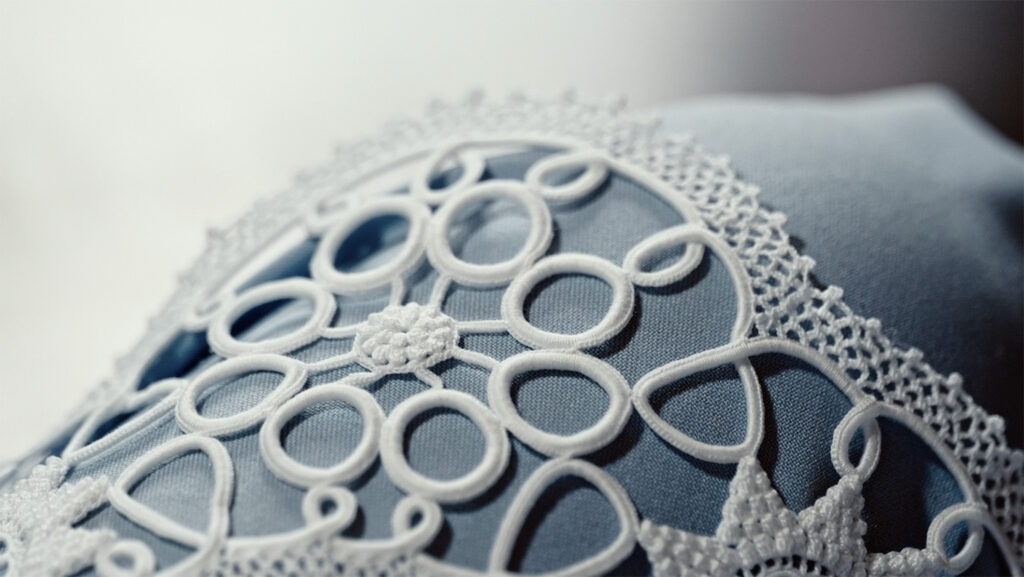

The manufacturing process of lace is a meticulous task that requires skill and patience. Each piece can take weeks or even months to complete, depending on its complexity. From selecting the materials to finishing the smallest details, the handcrafted production of Pico lace follows a sequence that remains true to its origins, with some innovations over time.

HOW LACE IS MADE

The lace making process begins with designing the pattern, which can be drawn by hand or follow traditional templates passed down through generations. The lace maker uses a fine needle and thread, usually cotton or linen, to start weaving the pattern with delicate stitches. In some cases, the process begins with preparing the fabric, where marks are drawn or outlines are basted to guide the lace stitching.

Each stitch must be adjusted precisely to ensure the design remains firm and detailed throughout the piece. Some of the most commonly used stitches include blanket stitch, cord stitch and knot stitch, which create different textures and reliefs in the lace.

MATERIALS AND TOOLS USED

The materials used in lace production mainly include cotton or linen thread, which can vary in thickness depending on the type of lace being created. In addition to the thread, lace makers use other essential tools, such as:

Farpa: A small stick or tool that helps to separate and hold the threads during the work, creating the characteristic peaks or frills of Pico lace.

Stick: Used to maintain the tension of the threads or to align parts of the lace as the piece is being worked on.

Thin needles: Lace makers use very thin needles, suitable for the delicate work involved in creating small lace stitches.

Additionally, pillows are used to support bobbin lace work when needed, and paper or fabric templates guide the lace maker in following the desired pattern.

THE EVOLUTION OF TECHNIQUES OVER TIME

The techniques used in Pico lace production have remained quite faithful to past traditions but have evolved over time, especially in terms of finishing and adapting to new market demands. In the 19th and 20th centuries, farpa lace became very popular and continues to be one of the most valued styles. However, with technological advancements, some lace makers have started using more sophisticated templates and pre-designed patterns to speed up the production process, while still relying on manual work as the primary method.

Newer generations of lace makers have also explored the use of modern materials, such as synthetic threads or fiber blends, to give the lace a more contemporary and durable touch.

INNOVATIONS AND THE FUTURE

Pico lace is experiencing a period of renewal, driven by a new generation of lace makers and a growing interest in keeping this tradition alive. With the support of training programs and exhibitions, Pico lace is being rediscovered by a wider audience that appreciates both the beauty and cultural significance of this craft.

NEW GENERATIONS OF LACE MAKERS

The new generations of lace makers are bringing fresh vitality to the art of Pico lace. Young women, many of them descendants of traditional lace makers, are learning the techniques and adapting to new market realities, which demand unique, high-quality handcrafted pieces. Local craft schools have played a significant role in training these young artisans, ensuring that the knowledge is preserved and the tradition continues to thrive.

INNOVATION IN LACE

Innovation in Pico lace involves both the introduction of new materials and the adaptation of traditional patterns and techniques to modern contexts. Some lace makers are experimenting with different colors and thread blends, creating more contemporary pieces that retain the essence of traditional lace but with a modern twist. Additionally, new technologies, such as laser cutting machines and digital templates, are being integrated into the creation process, allowing greater precision and production speed without compromising the artisanal quality.

INNOVATION WITH JOANA VASCONCELOS

For over 18 years, Joana Vasconcelos’ atelier has worked with lace produced in Portugal, used as second skins for various pieces. Her intention has always been to showcase national craftsmanship in this field. To ensure every piece was unique, focusing on originality, Joana Vasconcelos’ atelier traveled across the country searching for different lace designs until reaching Pico Island.

In 2006, Joana Vasconcelos decided to invite the lace makers of Pico Island to take part in one of her greatest undertakings ever: the production of hundreds of roses and rosettes that formed the “second skin” of Rafael Bordalo Pinheiro’s faience pieces, painted with ceramic glaze.

Maria Lucília, from São Mateus, led the commission, distributing the work among the remaining active lace makers on Pico Island, who produced various roses, rosettes, and squares.

Since 2021, Pico lace has been showcased around the world through Joana Vasconcelos’ creations.

EXHIBITIONS, AWARDS AND NEW TRENDS

Pico lace has been showcased in various exhibitions both regionally and internationally. Events such as craft fairs and cultural exhibitions have helped promote the work of lace makers and bring visibility to this art form. Some lace makers have been awarded for their work, standing out for their innovation and ability to keep this ancient tradition alive.

In recent years, new trends have emerged, such as incorporating lace into contemporary clothing and interior design, which has expanded market opportunities for these pieces, creating a promising future for the tradition of Pico lace.